Odor assessment of plastic recyclates

Hyperspectral Imaging (HSI)

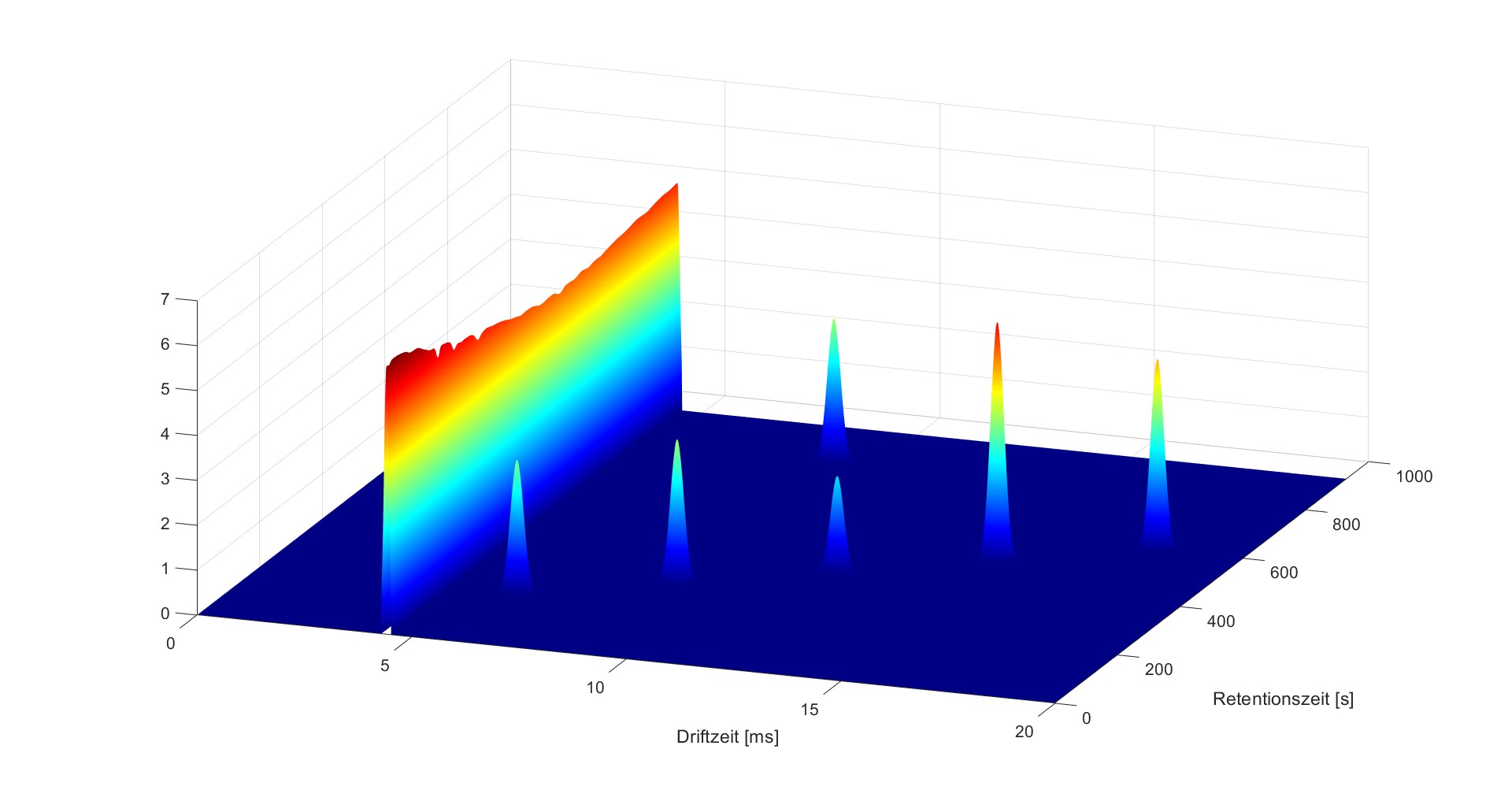

Every surface and every material has its own spectral signature. This characteristic signature can be recorded with a hyperspectral camera. Algorithms evaluate the signatures and assign them to qualitative and quantitative properties of the measurement objects.

Functionality HSI

Like a scanner, many hyperspectral cameras capture their images line by line. For this purpose, the sample to be examined is moved under the camera. A characteristic spectrum of the measured object within a defined wavelength range is detected in each image point.

Data evaluation in real time

Modern evaluation methods allow very detailed information about the measured object to be generated in real time from the highly complex measurement data. For example, the quantitative chemical composition of food can be determined. The method also enables the detection of foreign objects as well as the detection of quality deviations or contamination of individual objects in the production flow. Continuous data acquisition and evaluation enables complete coverage of the entire product flow. The often time-consuming and unrepresentative taking of random samples is no longer necessary.

HSI integration into your operation

With our HSI modules, objects from a few micrometers up to 60 cm can be analyzed in the wavelength range of 400 – 2500 nm. Our laboratory first performs preliminary examinations of your measurement objects and material samples. Based on the results, we configure a customized in-process system for you, integrating special AI-based evaluation methods.

PDF Hyperspectral Imaging

Contact

Florian Meuche

Department Manager Equipment Development

phone +49 3603 – 833 194

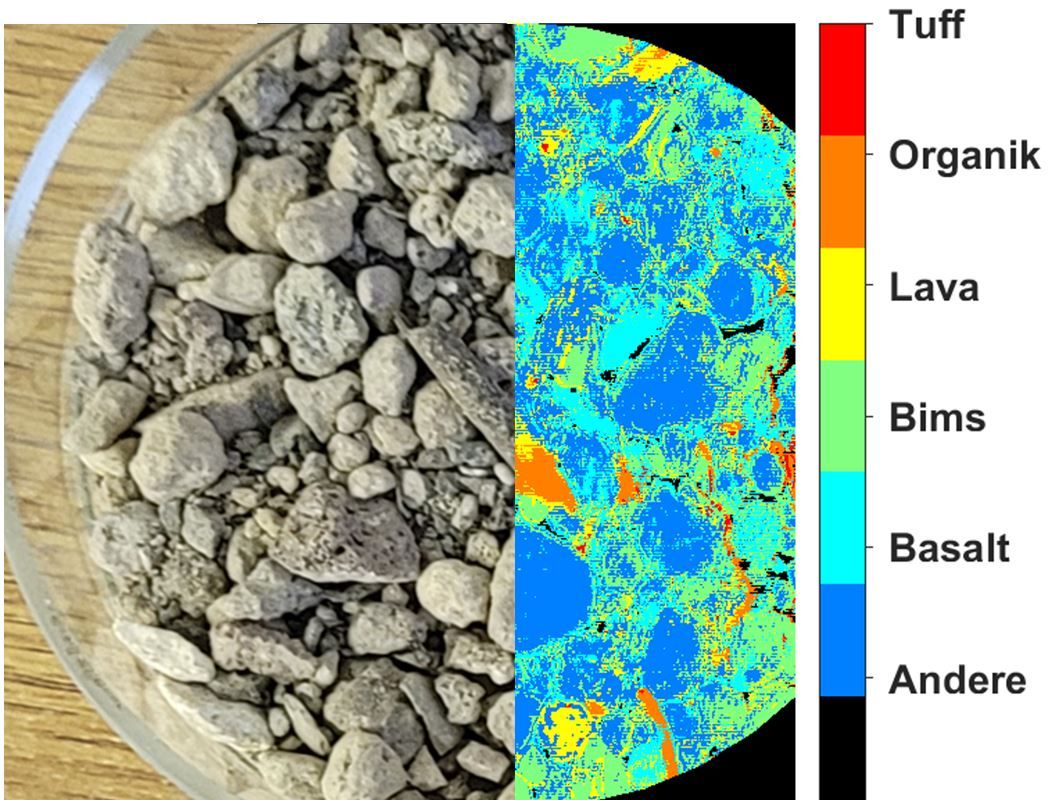

Classification of building materials in the recycling process

Hyperspectral Imaging (HSI)

Every surface and every material has its own spectral signature. This characteristic signature can be recorded with a hyperspectral camera. Algorithms evaluate the signatures and assign them to qualitative and quantitative properties of the measurement objects.

Functionality HSI

Like a scanner, many hyperspectral cameras capture their images line by line. For this purpose, the sample to be examined is moved under the camera. A characteristic spectrum of the measured object within a defined wavelength range is detected in each image point.

Data evaluation in real time

Modern evaluation methods allow very detailed information about the measured object to be generated in real time from the highly complex measurement data. For example, the quantitative chemical composition of food can be determined. The method also enables the detection of foreign objects as well as the detection of quality deviations or contamination of individual objects in the production flow. Continuous data acquisition and evaluation enables complete coverage of the entire product flow. The often time-consuming and unrepresentative taking of random samples is no longer necessary.

HSI integration into your operation

With our HSI modules, objects from a few micrometers up to 60 cm can be analyzed in the wavelength range of 400 – 2500 nm. Our laboratory first performs preliminary examinations of your measurement objects and material samples. Based on the results, we configure a customized in-process system for you, integrating special AI-based evaluation methods.

PDF Hyperspectral Imaging

Contact

Florian Meuche

Department Manager Equipment Development

phone +49 3603 – 833 194