HSI analysis by spectral signature

Analysis using hyperspectral imaging (HSI) adds a third dimension to the possibilities of well-established infrared spectroscopy. Hyperspectral analysis allows chemical and physical material properties and/or ingredients of an object to be determined with spatial resolution.

With the HSI method, a complete spectrogram of each image pixel of an object is recorded and evaluated. This adds a third dimension to the two-dimensional image information.

As with a scanner, the images are recorded line by line. To do this, the sample to be examined is moved under the hyperspectral camera. The spectrum of the measured object is detected within a defined wavelength range in each captured pixel.

Special algorithms evaluate the spectral signatures and then assign them to qualitative and quantitative properties of the measurement objects.

Compared to conventional laboratory analysis, hyperspectral imaging requires much less sample preparation and is much cheaper to operate.

Data evaluation in real time

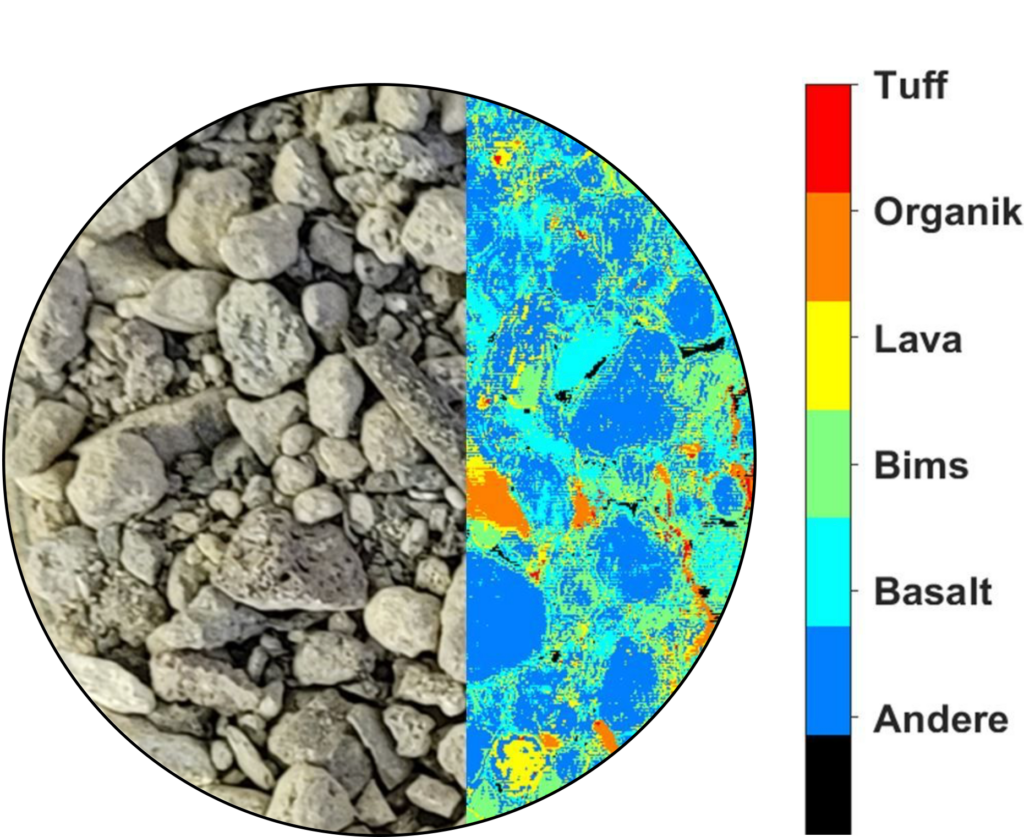

Modern evaluation methods are based on AI-supported chemometric models. This makes it possible to generate very detailed information about the measured object in real time from the highly complex measurement data (here, for example, the composition of building rubble).

Continuous data acquisition and evaluation can detect foreign objects and/or quality deviations of individual objects in the production flow. The often time-consuming and unrepresentative taking of random samples is no longer necessary.

Example of inline process control of food

HSI analysis using the example of strawberries

Strawberries are a very sensitive food for storage and transportation. Overripe fruit or severe bruising of the fruit tissue (bruising) usually leads to infections caused by molds. Their toxins, known as mycotoxins, can be very dangerous for humans.

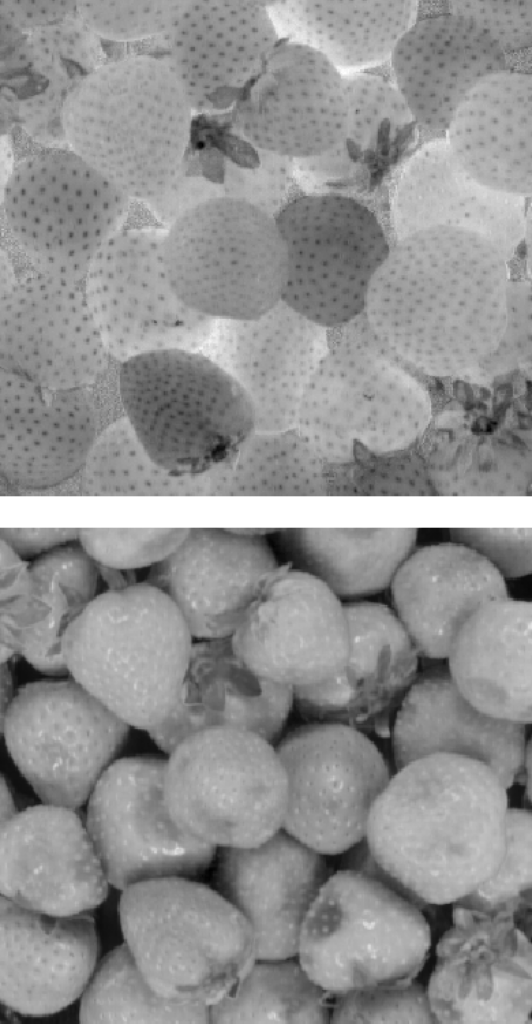

The hyperspectral analysis makes it possible to recognize the degree of ripeness of the fruit (top image) in real time (shown here the darker the riper).

However, HSI imaging can also be used to determine other parameters using the same measurement. The image below shows the detection of pressure points in the amniotic tissue (shown here as dark discolorations).

Continuous data acquisition and evaluation enables the detection of quality deviations of individual objects in the production flow.

Further applications of hyperspectral imaging

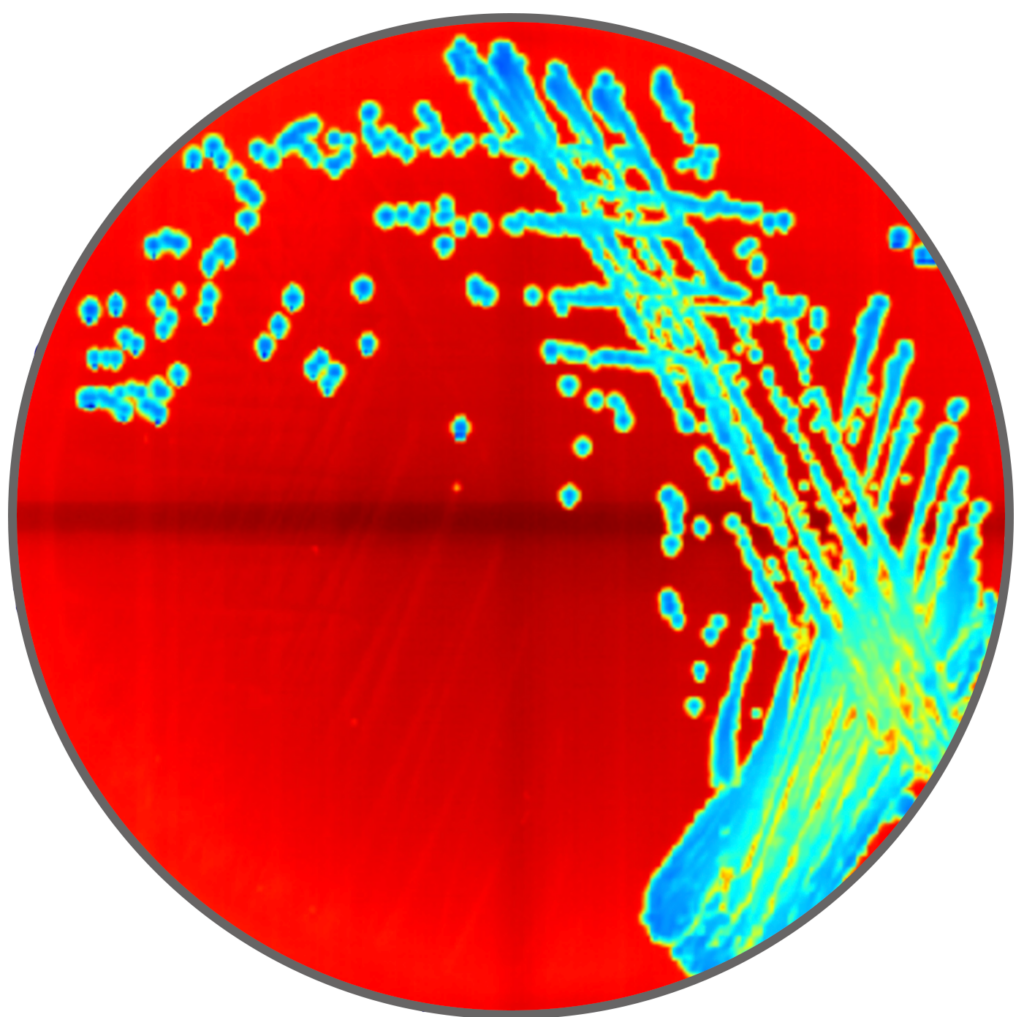

Automatic classification of microorganisms

Using hyperspectral imaging, we develop AI-based classification methods for the rapid and automated detection of clinically and food-relevant germs on culture media. This process enables automated primary reading and reduces the workload of microbiology specialists.

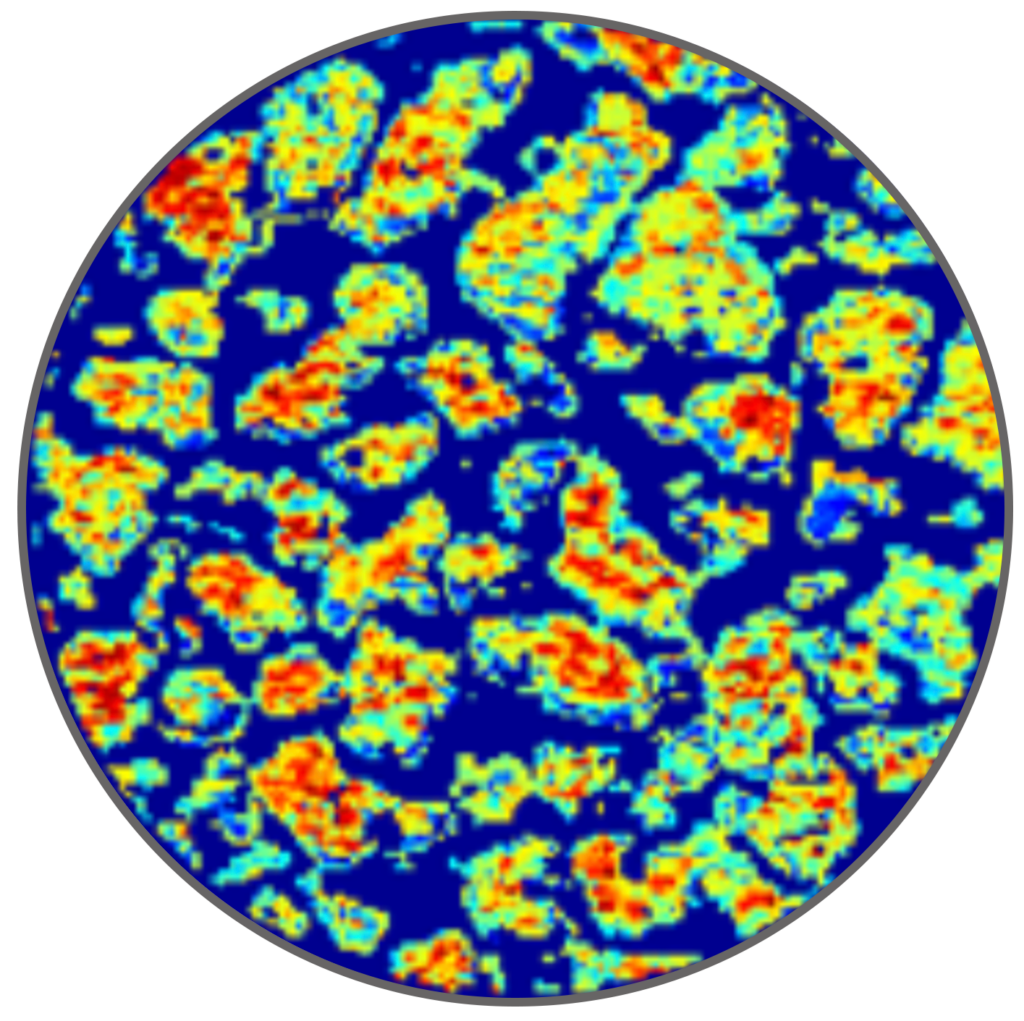

Active ingredient distribution in granules and powders

Using hyperspectral imaging, we develop methods for the continuous monitoring of relevant product parameters during granulation and after tableting is complete. This enables quality deviations to be detected during the manufacturing process.

HSI integration into your operation

With our HSI modules, objects from a few micrometers up to 60 cm can be analyzed in the wavelength range of 400 – 2500 nm.

Our laboratory first performs preliminary examinations of your measurement objects and material samples. Based on the results, we configure a customized in-process system for you, integrating special AI-based evaluation methods.

Contact

Florian Meuche

Department Manager Equipment Development

phone +49 3603 – 833 194